How To Make Leather In 23 Steps

Leather is probably one of the most exquisite and durable textures available in the world. Creative artisans have found a way to incorporate leather finishing into practically anything possible. Ranging from belts to shoes to furniture and even to high-end designer bags made available by award-winning designers.

It’s rather obvious to see why this seemingly high-end merchandise would remain a winner. Even if it means to give accessories a classic and timeless look. The production has evolved to suit the unique tastes of people from diverse cultures. While effectively blending with the current modern ambience.

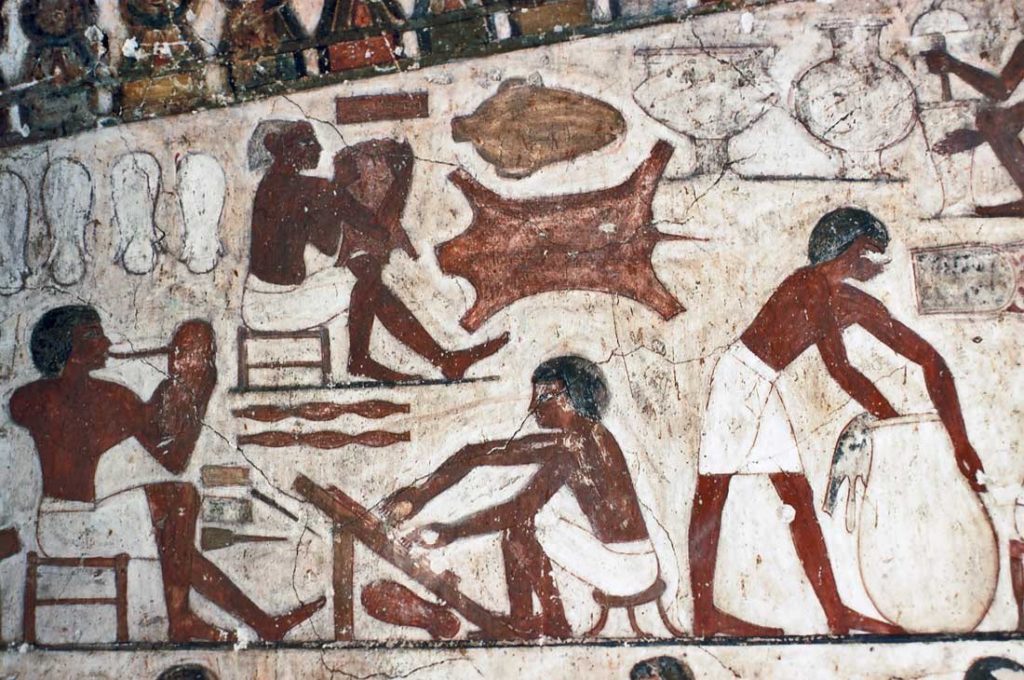

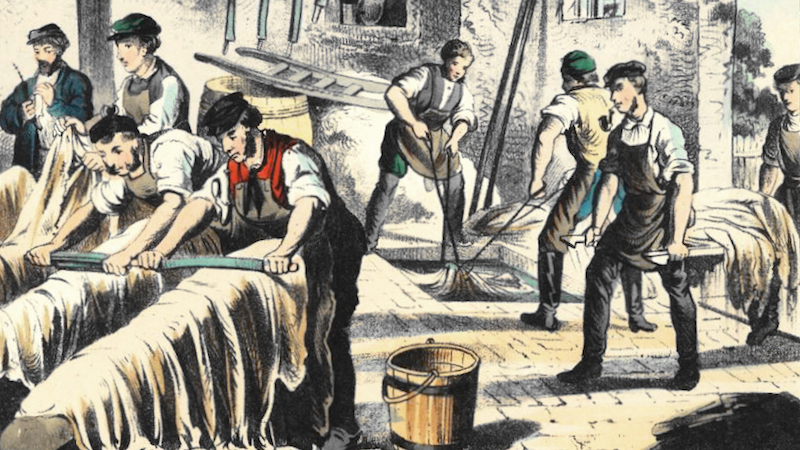

Most people are unaware of the rich cultural history surrounding the ancient art of leather-making. While taking time to discover the effort required in making products. You might realize that those seemingly high-end accessories and merchandise are worth every pound placed on them. The art of leather production is a process that has been in existence for over 7000 years.

Throughout history, leathers are basically animal skin or hides that have undergone severe modifications and treatments to make them suitable to use as items of clothing, furniture, or footwear. With the rise in technology and eco-sustainable culture in fashion, vegan alternatives and substitutes have also popped up providing high value without having to use animals as the main source.

Brief History about Leather

The Egyptians and Hebrews around 40BC discovered the original process of tanning. At the middle age, the Arabs were famous to possess superior leather production methods. By the 15th century, the process of production had majorly spread to European countries. By the 19th century, the Europeans ushered this art to its first new mechanical advancement era that allows the production on a global scale. Since this transition, the UK was one of the highest leather producing countries. Being one of the countries with the leading amount of specialists, leather goods in the UK is of top quality. This guide to leather making helps awaken a sense of appreciation for the intense effort invested in producing various finishings.

Step by Step Guide To Leather Making

Curing

A first step process of preserving rawhides to prevent deterioration. This process employs by using salt to induce an osmotic process that encourages the loss of moisture as a form of preservation and inhibits the growth of bacteria.

Soaking

Preserved dehydrated leather is rehydrated with protease and carbohydrate to restore the hide to a flaccid and malleable condition. It can help to unburden the skin or hide of unwanted contaminants like dirt and grease.

Painting

The skin or hide is coated with a mixture of “paint” made of hydrated lime, sodium sulfide, and water, which penetrates the corium and dissolves the keratin cells of the hair root. In summary, basically an unhairing process.

Liming

The hides are soaked in an alkali solution to loosen the top skin and hair layer, dissolve meat and fat residue and neutralize proteins or keratin materials that affect the quality in making leather products.

Fleshing

The liming process loosens the skin and meat, the fleshing process manually and carefully excavates left out flesh without damaging the skin or hide.

Deliming

The initial painting process causes an increase in the alkali PH level of the skin. The deliming process works by slowly lowering the alkali PH levels with the use of ammonium salts.

Bating

The main goal of the bating process is to create a pliable hide and prepare them for the tanning process. By using proteases to dissolve unwanted proteins and scuds, producing a smoother and softer hide surface.

Pickling

Pickling is used to reduce the PH of the hide prior to the tanning process to create an environment for optimal penetration of subsequent tanning minerals. This involves treating the pelt with a basic solution of sulphuric acid and common salt to increase the acidity and prevent swelling respectively.

Degreasing

A high amount of fat might prevent uniform spreading of tanning dyes and chemicals, causing difficulties in the overall finishing processing and creating dark and greasy stains.

Tanning

This involves the process of treating skin and hides using chromium(III) solution to permanently alter the protein structure.

Splitting

Leather is split after the original tanning to produce the top layer, which is known as the full-grain and is known to have higher malleability and durability. The other section, “the other side”, which is made of lower quality leather and can only be practical after treatment and coating.

Shaving

The shaving process goes hand in hand with splitting. By practically scraping the flesh side of the leather until the desired thickness is obtained. It can be described as the finishing touch to the splitting process.

Neutralisation

In discovering how to make leather, neutralization remains one of the most complex processes. The hide is neutralize by weak alkaline reagents like ammonium sulfate and sodium bicarbonate. This is done to make the leather susceptible for the further dyeing process.

Dyeing

This phase is also referred to as the re-tanning process. The leather’s original colour is initially determined by the tanning process, which gives it a brownish or yellowish colour. The need for a more extensive colour range initiated the process of dying. Three methods help to achieve this, which includes; spray dyeing, dip dyeing, and brush dying.

Fatliquoring

Leather naturally does not contain enough oil naturally to keep it lubricated and supple after the rigorous process of tanning. The fatliquoring process introduces a fat emulsion to make the leather softer and improve the physical characteristic of the finished product.

Samming

This process helps to further reduce water content by up to 55%.

Setting Out

This involves further evening out the skin moisture content, and surface flattening and smoothening to improve leather quality. In some machines, the surface flattening is achieved with a blade and the “felt sleeve” absorbs the fat.

Final Drying

A suitable leather is optimally preferred to have a 20% water content. To achieve this, there are various drying processes that can be involved. Hanging, vacuum drying, hot-air drying, high-frequency drying and glass drying. Selling leather is on the basis of its surface area, so the drying method has to be chose selectively in relation to how it affects the size of the leather.

Staking And Dry Drumming

The leather is placed in a rotating drum for rigorous tumbling. This process serves to soften and improve flexibility.

Buffing And Brushing

Mechanical rubbing helps to remove extra hanging effects to create a suede quality. Buffing of the grain map to create an extra smooth surface. After the buffing process, removal of excessive dust helps create an elegant look.

Finishing

This involves the mechanical process of shaping and smoothing the leather. The final application of a chemical process to lubricate, soften and colour. The process involved in this broad term varies, ranging from rolling to polishing in order to satisfy the texture, gloss or surface required in the final product.

Final Grading

The varying methods chosen would determine the quality or grade of the finished product. The grade spectrum available includes; split-grain, full-grain, top-grain, genuine and bonded.

Measurement

This final process serves as one of the most important guides to making and distribution as selling the leather is on the basis of accurate surface area measurement.

Leather making is an age-long art, which has undergone several changes over time. With these 23 steps listed above, you can be sure to have your own production complete in no time.

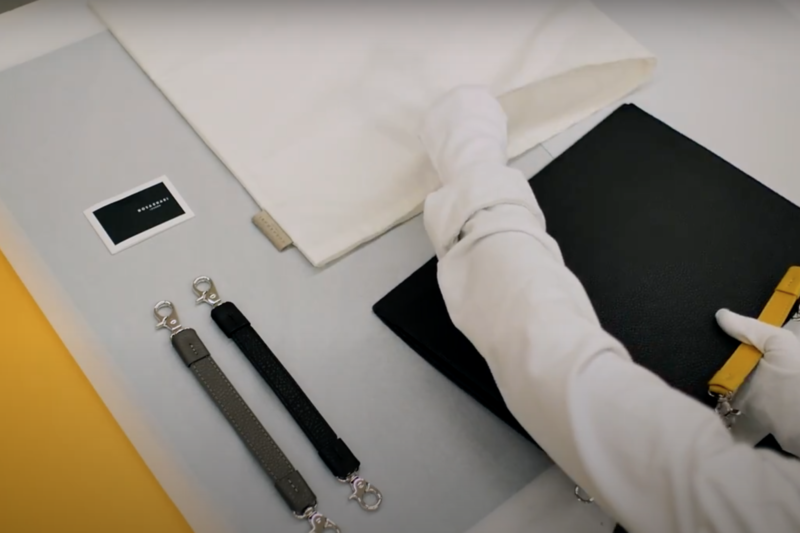

CreateLab for your leather business

Our design team is ready and open to any design challenges when it comes to leather. We focus on bringing the best technical and design solutions, collaborating on one, ensuring the design is seamless and exactly to your wishes.

If you are planning to scale your leather business in the UK, Createlab can help your plans become reality. We offer consultation on leather business and industry, provide prototyping and also help you decide the best leather for your product.

Feel free to reach out to us here.

RELATED ARTICLES

MAKING LEATHER TIMELESS: NOSAKHARI’S MISSION TO CELEBRATE DIFFERENCE IN THE MODERN WORLD

LUXURIOUS LEATHER CHECKLIST: WHAT TO KNOW BEFORE YOU BUY

PLANNING YOUR FIRST MEETING WITH A LEATHER MANUFACTURER

HOW TO CREATE A BESPOKE CUSTOM-MADE LEATHER WALLET

TO PREPARE FOR YOUR DESIGN CONSULTATION

HOW SAMPLE MAKING COULD SAVE YOUR LEATHER INNOVATIONS FROM “DEVELOPMENT HELL”

TOP 3 LEATHER MANUFACTURING TRENDS THAT ARE CHANGING THE FUTURE OF FASHION