Sample making is the last and arguably the most crucial step of creating a luxury leather item. While the previous stages of manufacturing leather goods give the creator a functionality and design idea, the sample making brings your product to life. Using your directions and materials from the previous stages of the design process, a leather sample maker will make several samples of your leather item, each suited for different functions.

Leather Sample Making Starts With Pattern Making

The initial stage of leather goods’ sample making starts with pattern making. During the pattern-making phase, a leather proto sample reflects your design. This prototype showcases the measurements, functionality, and uniqueness of your product design. A reputable leather good’s sample maker might quickly make the leather goods sample for you. But, the benefit of using a full-service leather goods manufacturer like CreateLab is that we can help you avoid hiccups and make recommendations on every step of your leather goods launch.

How Leather Good’s Sample-Making Works

Once you have a design sketched out and ready to go, you would get in touch with the leather good’s manufacturer to arrange a meeting to discuss the design of your leather accessory. They would have a leather manufacturing factory in which they can create your leather sample.

This is a vital step in the process because your leather goods manufacturer may have important visions and recommendations into design creation that may affect the complete outcome of the leather product. This can change the design and cost of the pattern and sample.

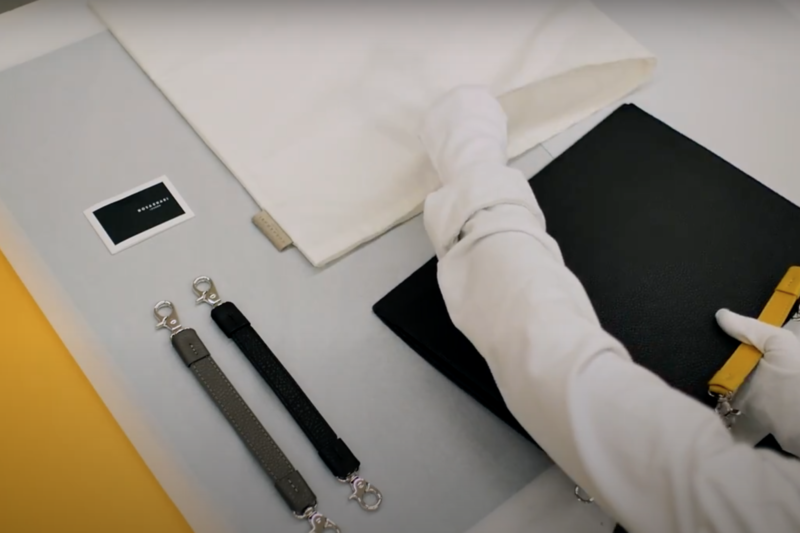

After the meeting where everything from stitching to pockets and functionality is decided, the manufacturer can help you source the leather, chains, straps, zips and so on.

Once the sample is finished, it’s a good idea to test out your leather product for functionality and use. If you’ve made a leather handbag for example, then use it daily, walk around crowded streets and tube stations with your leather handbag. By wearing the leather bag, you will understand the design flaws, such as the straps being too short, or the interior pockets needing extra space.

Corrections from any errors found in the first sample are applied in the second sample. Now it’s time to test out your second sample and, most of the time, go to the next step of the process. However, sometimes leather design creators may find that the sample step takes several attempts. Alternatively, leather goods designers might even come across some samples that do not make it past the sample phase at all – they scrap the idea and start again.

Samples Helping Your Innovations From Developmental Hell

Sample making is one of the crucial elements of the pre-production processes in the fashion industry. Before a manufacturer produces bulk orders, a prior sampling of styles is done to get approvals and jumpstart the construction of leather accessories. Imagine if a bulk order is placed where the testing of the sample is not done correctly and find the product lacks certain aspects of functionality?

You could be potentially setting yourself up for developmental hell – please keep in mind that even the most innovative and experienced leatherworker might make sample orders.

CreateLab Make Leather Samples And Production-Ready Prototypes

Want a production-ready prototype? Or you would like to improve or refine? We can assist you in every step of the design process, from hand-drawn sketch work to a 3D conceptual design. CreateLab can help build excellent prototypes that evoke your unique design philosophy and our uncompromising attention to detail.

Your sample needs to have a good quality assurance and a finalised design of all the components of your product. Sampling is cost-effective, helps rectify errors to perfect your merchandise and deliver quality that your brand deserves.

We have our design team ready and open to any design challenges. We focus on bringing the best technical and design solutions, collaborating one on one, ensuring the design is seamless and exactly what you wished all along. Send us your plans to discuss your ideas further, and we can help you build first-class samples, delivering each piece to the client’s satisfaction.

RELATED ARTICLES

MAKING LEATHER TIMELESS: NOSAKHARI’S MISSION TO CELEBRATE DIFFERENCE IN THE MODERN WORLD

WHY LEATHER MANUFACTURERS CARE WHEN SOURCING THEIR GOODS

TOP 3 LEATHER MANUFACTURING TRENDS THAT ARE CHANGING THE FUTURE OF FASHION

FROM SKETCH TO STORES: LONDON’S LEATHER FASHION JOURNEY

8 BENEFITS OF MANUFACTURING YOUR LEATHER GOODS LOCALLY

HOW TO PREPARE FOR YOUR DESIGN CONSULTATION

TOP 3 LEATHER MANUFACTURING TRENDS THAT ARE CHANGING THE FUTURE OF FASHION