Top 4 Leather Manufacturing Trends That Are Changing the Future of Fashion

The leather fashion industry has always been the centre for innovation — from the invention of the sewing machine to the rise of e-commerce, it has changed practices to help the leather industry move forward confidently. Much like technology, the leather fashion industry is progressive and cyclic.

Leather is one of the most extensively traded items in the world, which explains why the leather and leather goods industry plays a projecting role in the world’s economy.

During the last 30 years, the leather goods industry has undergone significant changes due to factors such as:

- the escalation of living standards and labour costs in places that produce leather goods

- the rise of marketing and brand strategies

- the distribution of activities through outsourcing production

- new methods in technological processes

Economic Importance of the Leather Industry in Europe

Around 36,000 enterprises are involved in the leathers and related goods sector with a turnover of EUR 48 billion. The companies have around 435,000 employees working in the leather industry in Europe only.

In terms of leather and raw material, the EU is the source of the highest quality of calfskins. Tanneries are usually families, small and medium-sized companies in Europe. Since the past, regional concentration is intense, and the industry is often the dominant creator of wealth and jobs in the local economy.

Here Are 4 Major Leather Manufacturing Trends That Are Changing The Future Of Fashion:

Product Design Trends Are Changing Due To Technology

Technology advancement in recent times has been automating the fashion designer’s manufacturing process.

Leather fashion companies of all sizes and speciality areas are using technology to understand customers’ buying journey better than ever before. Artificial Intelligence helps the leather retail industry to forecast, plot and promote leather fashion items while refining product availability and predict deliveries.

The ideal situation of leather product designers is to know what the next trend will be and avoid overproduction. Today Artificial Intelligence (AI) is allowing to forecast trends and sales, allowing brands to comprehend consumer patterns and predict their production levels. This has helped leather manufactures to massively extract their ideas to what is likely to sell.

Optimisation Of The Leather Industry Supply Chain

One of today’s major leather manufacturing trends is merging your vendor list. In today’s fast-turning world, consumers expect prompt supply and instant delivery. The long lead time of traditional leather manufacturing is no longer a feasible option for brands looking to preserve a competitive edge.

Numerous companies are using leather manufacturing technology to put design, material sourcing, manufacturing, and delivery all in one place in an on-demand arrangement using cloud-based technology. This full-service manufacturing trend offers wide-ranging automation, which reduces leather production time and waste and speeds up the entire supply chain.

Data Analysis To Minimise Leather Goods’ Inventory

Reducing inventory is one of the leather manufacturing trends many companies have been following in recent times. With the help of data analysis for manufacturing technology, limiting the production list is far more easier now. With real-time feedback, cloud-based inventory management solutions, and live manufacture monitoring throughout the leather production process, companies can keep a closer eye on what leather items are being produced.

The trend toward data analysis in the fashion sector is also being extended for communication and predicting. Quick updates from design to manufacturing update communication between factory and retailer instantly, while data collection during fashion shows and in stores are serving companies to govern real-time inventory requirements and predict future leather fashion needs.

Eco-Leather For The Future

Eco-leather is made of natural fibres, such as flax or cotton, combined with palm, corn, soy, and other oils laminated together in layers, which offer the appearance that it comes from an animal.

Simply speaking, it’s a fantastic alternative. In comparison to toxic chrome-tanning, eco-materials are renewable and have a low carbon footprint.

But since, the result is smooth, hard to work with and stitch breaks on the flip side, leather shoes are still not available with this option. Yet, there is hope for the future.

There is ever-growing demand of eco-leather material in the leather industry. Giant brands such as Nike, Puma and Adidas to send out samples to produce leather prototypes every year.

The substitute can be worth waiting if we can use plants to make biobased material which substitutes for leather, which has a beneficial side to the environmental and social concerns.

Designers like the concept of an alternative as it gives them a whole new design element, which they did not have before when they tried to work with artificial leather such as polyvinyl chloride( PVC).

Contact Createlab For Forward-thinking Leather Manufacturing

A lengthened timeline of deliverables, high minimum order quantities, and geographically spread supply chain are three manufacturing trends of the past that will not work for the leather fashion industry, which shows that traditional supply chains don’t give businesses the environment they need to succeed.

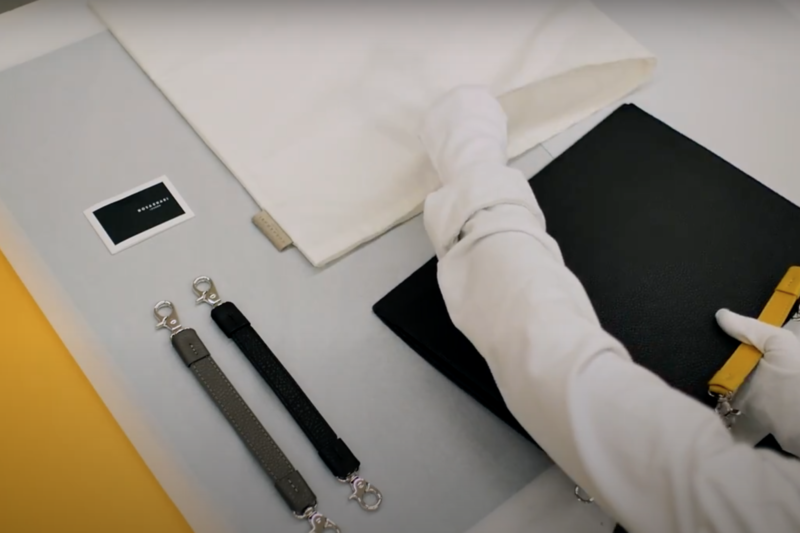

Manufacturing technology, such as on-demand manufacturing allows companies to shorten lead times and improve customer satisfaction by increasing their ability to fulfil orders with precision and quality. Contact CreateLab to help better understand how you can streamline your leather innovations manufacturing processes.

RELATED ARTICLES

MAKING LEATHER TIMELESS: NOSAKHARI’S MISSION TO CELEBRATE DIFFERENCE IN THE MODERN WORLD

HOW SAMPLE MAKING COULD SAVE YOUR LEATHER INNOVATIONS FROM “DEVELOPMENT HELL”

PLANNING YOUR FIRST MEETING WITH A LEATHER MANUFACTURER

FROM SKETCH TO STORES: LONDON’S LEATHER FASHION JOURNEY

8 BENEFITS OF MANUFACTURING YOUR LEATHER GOODS LOCALLY

HOW TO PREPARE FOR YOUR DESIGN CONSULTATION