How Is Leather Tanned?

Has leather tanning been the question on your mind? Or have you just wanted to satisfy your curiosity about the wonders of the leather product? Well, tanning of leather involves a lot of steps and this will be simplified in this article.

Tanning hide into leather involves a process which permanently alters the protein structure of the skin, making it more durable and less susceptible to decomposition, and also possibly colouring it. Before tanning, the skins are dehaired, degreased, desalted and soaked in water over a period of six hours to two days. Historically this process was considered a noxious or “odoriferous trade” and relegated to the outskirts of town.

Follow closely as we do a quick study on how to tan leather from the point of rawhide to the point where it is useable and wearable.

Stage 1: Remove the hair and fat

The first thing to do on your animal skin is to remove the hair and fat. This is done immediately the hide is found but if it would be left for a later time, them other processes like curing and soaking will precede this. In the process of hair removal, hair agents like calcium hydrochloride and sodium hydroxide are necessities. These agents will aid easy removal of the hair from the skin as it passes through a machine. After taking the hide through a machine, the leftover hair will then undergone a manual removal. Some would prefer to use a knife that is not so sharp and others will just use a plate-like object with a smooth dull edge. Either way, this stage of your leather tan will still be possible.

Stage 2: Bating and pickling

Now, this process is more specific because the end use of the leather-in-making would be considered here. In the bating process, enzymes are added to the hides. Since these enzymes help to soften the hide, the level of thickness or softness that would be achieved would be in check. But if the hide has undergone the lime process in the first stage, then a delimiting would be necessary before bating.

On the other pickling involves using salt and acid on the hide. Note that the salt would always precede the acid because it helps reduce the intensity of the acid that would be used on the skin. When this is done, you can be sure to penetrate the skin with any tanning agent of your choice.

Stage 3: Tanning

This stage is the main stage for the leather tanning process. This process can be done using different methods. All of these methods are focused on keeping the leather free from bacteria growth or decomposition of any kind. The various forms of leather tanning are highlighted below.

1) Veg Tan

This process of tanning uses vegetables just as the name already spells out. In this process, the skin is dipped into a big pit that contains a combination of tree and plant types. These tannins used on the hide transform it to become a veg tan leather. Although this process takes time and involves extra skills from experts, the beautiful earth smelling outcome always pays off.

2) Chrome Tan

This tan method is also named after the main ingredient, chromium, which is used in the leather tanning. This method is much faster than the veg tan and thereby adapted by many over the years. In fact, almost all the leather company in the UK would go for a chrome tan to any other one. The chemical that is used in this process is called Chromium (IIIl) sulphate and this chemical can hasten the tanning to a maximum of a day compared to months of veg tan. Of all the leather types, the chrome tan leather is mostly available among the leather in the UK because it involves less labour to produce solid leather.

3) Oil Tan

This form of tanning is simple and easy to do with the hands. This process of producing an oil tan leather involves an application of animal oil or any other natural oil like fish oil or claw oil to the body of the hide. This form of tanning will help the skin to be more flexible and this makes it a good option for shoes.

4) Brain Tan

This is a very interesting method of tanning because it needs the brain of the animal to tan the skin. The brain contains just the right agent to produce any brain tan leather you desire. All that is needed is to apply the brain after it has been marched, to the skin which would do the magic of tanning it well. Although this process is straightforward, it cannot still be done without an expert touch that makes it come out softer and better.

5) Natural Tan

The conditions present in bogs, including highly acidic water, low temperature, and a lack of oxygen, combine to preserve but severely tan the skin of bog bodies.

There is another form of tanning that is used by the most leather company to produce a kind of leather called Latigo. Everybody asks what is latigo and the simple answer is that it is also a form of leather that was tanned with two other popular tanning methods. Unlike rawhide which does not go through any form of tanning at all, the latigo goes through double. The latigo leather comes about after a leather which has been chrome tanned, undergoes a veg tanning. Although, there is no single name for leather that has undergone this process just the Latigo leather would do for a perfect description.

Stage 4: Finishing

After the skin has been tanned using any of the listed tanning methods, then the finishing stage comes next. In this finishing stage, the leather will undergo drying which is done immediately after the tanning process to dry off the mixture that the leather has been exposed to.

The next thing that would be done in this stage is the application of oil. The leather is prone to breakage after drying, therefore, oil or perhaps grease is used to curtail the effect and increase the leather’s flexibility.

With this oiling completed and other special touches, the next finishing would be to apply colour. This can be done either by directly dyeing the leather or by simply applying pigments. The colour to be applied is totally by choice and could be done using any method of dying.

Every other finishing that comes after these will be for a specific design. If you want your leather to be well polished, you will finish it up with some polishing. If the leather needed is for making hard materials like sole, then extra finishes of compression should be done.

Conclusion

So, here you have it, the step by step process of leather tanning that will guide you through any tanning process. As it has been clearly stated, none of these processes can be skipped as they all work together to produce a well-tanned leather.

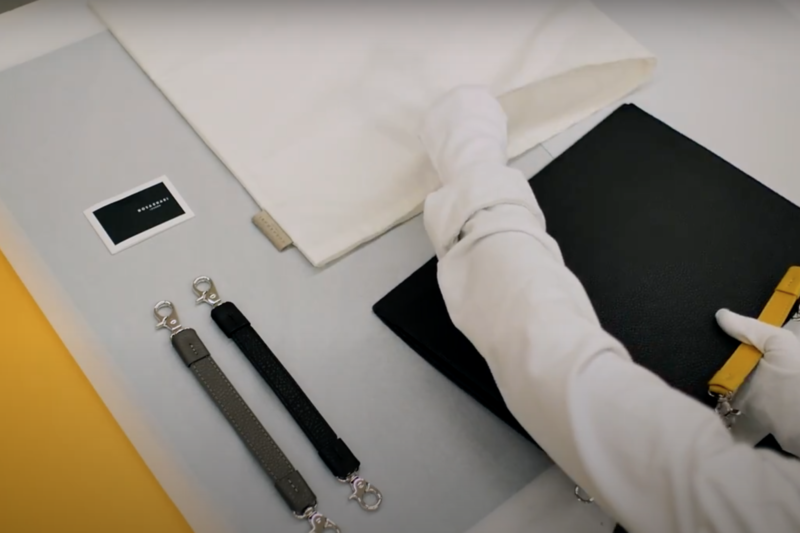

We, at CreateLab NoSakhari, aren’t just a leather manufacturing company in the UK, but we pride ourselves for bringing the best of leather products to our customers’ hands. Each process of creating the perfect handmade leather is well thought and made to express the individuality of everyone.

Feel free to contact us anytime if you are looking for a leather manufacturer or supplier in London.