Why Leather Manufacturers Care When Sourcing Their Goods

Leather manufacturers and artisans are on a mission to seek and source the finest hides from around the globe, to ensure that the quality of their leather goods is nothing far from perfection.

Once the finest hides are found, it’s the leather manufacturer’s job to dye the leather followed by finishing the leather to the customers’ exact specifications. Leather manufacturers have complete control over the entire leather-making process, and experienced craftspeople are on hand to inspect and certify excellence at every stage.

Aware That Genuine Leather Isn’t Real Leather

For some, this revelation may come as a shock, but others in the industry will know “Genuine leather” is the shaved-off underside of a full piece of leather. It is cleverly marketed, so genuine leather products are still attractive; however, they are prone to wear and tear, and is the least beautiful part of the hide. This is why leather manufacturers care when sourcing their goods because they will be looking for “Real Leather” which is full-grain or top-grain varieties – the only difference between these two is that top grain is lightly sanded for aesthetic reasons. The full-fibered character is a high-end luxury as it continues it accumulate character throughout its life.

High-quality Leather Begins With The Best Raw Materials

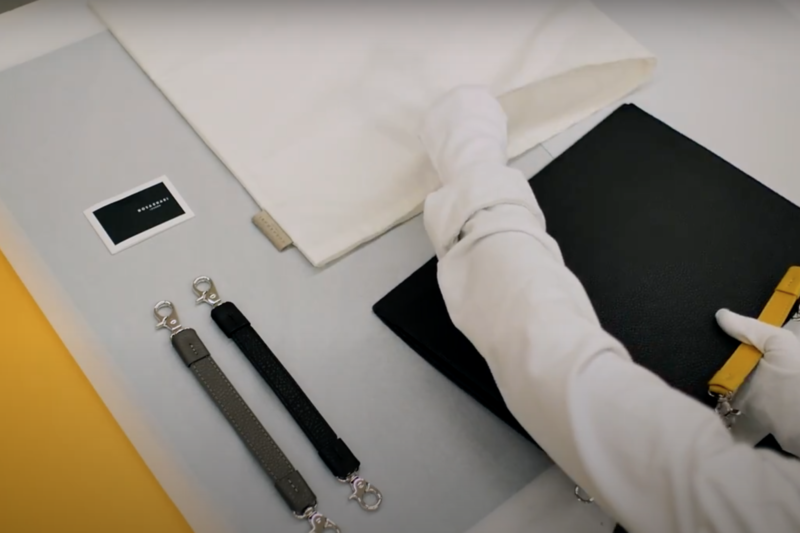

CreateLab prides themselves on accepting only the finest hides and skins from partner tanneries to ensure we are providing our customers with the best yield and value available.

Most of our leathers begin with the careful selection and control of crust which we procure from around the globe. We seek the best hides, which we consider to be a crucial point in producing the highest quality leather.

Sustainable Leather For The Future

Leather is made from dead animal skin and is never animal friendly. Hence, any kind of tanning and processing would always have a sort of environmental effect.

Hides come mainly from meat-raised animals; instead of consuming additional money, they are a byproduct of another field. Although vegetable tanning is more costly and does not always offer the required softness, it makes the leather more environmentally friendly.

It must be known that a continuum is being studied. It is not black or white, virtuous or illegal, contaminating or poisonous. Instead, leather production falls to an extent. Companies who wish to make them eco-friendly have to work according to international guidelines and best practices to achieve a minimum negative impact.

But leather tanning can certainly be greener and more sustainable than traditional methods allow – for instance, CreateLab Nosakhari range meets ambitious targets such as chrome-free tanning and solvent-free finishing. Salt treatments are also stopped, and water is conserved using only the freshest hides. Leather is manufactured under European environmental standards and does not use pentachlorophenol, organochloride or chlorofluorocarbons.

Leather Goods Made To Last

For the tannery, an extensive curing process is recommended that goes from soaking the leather to remove impurities through to dying and conditioning the leather to guarantee the best colour and durability possible. This ensures that the finished leather goods are of the finest quality and will look great for years to come.

Understanding Issues With Producing Leather

Consumers become more mindful of the atmosphere and have a lower tolerance for environmental waste and wasteful textile processing methods. Suppose fashion brands want to sell sustainable and environmentally friendly goods to their customers. In that case, their first step is selecting the leather from suppliers that comply with international environmental laws and standards.

Nosakhari, a London-based leather brand that works with premium leather bags and accessories, source their hides from the best in Europe. The company also produces leather prototypes for leather brands around the globe with an ethical work environment and healthy leather sourcing.

Quality Control Standards for Leather Manufacturers

A great leather manufacturer will ensure every order undergoes comprehensive quality check and tested to verify that it meets or exceeds the leather industry performance standards. As a leather manufacturer, controlling all production processes and retaining the exact formulas and retainer cuttings of every order is critical. So, it essential to have control over the variations of dye and produce previous dye lots to match every batch for years to come.

Highly Experienced In Sourcing Quality Leather

Sourcing the right type of leather involves a lot of work with different styles and options available for various purposes. We will help save your time and source the best quality or a specific leather you would want for your product.

Collectively we have a long history working with premium leather and helping our client source premium leather in various grades and thicknesses. Over the years, we have built relationships with multiple suppliers and tanneries who continue to provide us with the best of the best quality leather for producing leather goods.

We can help you source the leather starting from the size, tanning, thickness, grade selection, colour, and price. Let us know what you need and leave the rest to us.

RELATED ARTICLES

MAKING LEATHER TIMELESS: NOSAKHARI’S MISSION TO CELEBRATE DIFFERENCE IN THE MODERN WORLD

HOW SAMPLE MAKING COULD SAVE YOUR LEATHER INNOVATIONS FROM “DEVELOPMENT HELL”

TOP 3 LEATHER MANUFACTURING TRENDS THAT ARE CHANGING THE FUTURE OF FASHION

FROM SKETCH TO STORES: LONDON’S LEATHER FASHION JOURNEY

8 BENEFITS OF MANUFACTURING YOUR LEATHER GOODS LOCALLY

HOW TO PREPARE FOR YOUR DESIGN CONSULTATION

TOP 3 LEATHER MANUFACTURING TRENDS THAT ARE CHANGING THE FUTURE OF FASHION