White Leather: How Is It Made?

In today’s leather market, leather manufacturers are faced with a common problem – minimising the environmental impact that leathermaking processes have. Various eco-friendly methodologies are being developed to tackle the detrimental impact that leathermaking processes have on the environment.

Furthermore, regulatory pressures have meant that the tanning process has come under scrutiny, and the use of hazardous substances such as azo-dyes and chromium salts is no longer acceptable.

To provide a more sustainable alternative to these chemicals during the tanning process, the industry has seen the development of ‘white leather’. This leather is produced by a combination of synthetic tannins, vegetable tannins, glutaraldehydes and minerals, such as aluminium and zirconium.

The rise of white leather has witnessed extensive usage in manufacturing leathers such as automotive leathers, upholstery leather, garment leather and upper shoe leather.

This article will provide you with an overview of what white leather is, how it’s manufactured, and the various benefits it has over normal leather.

What is White Leather, And Why Does it Matter?

Characterised by a distinctive pale cream colour, white leather is produced by tanning the leather hide with non-chromium containing oxidising agents.

After undergoing this specific tanning process, the leather obtains a distinctive colour and is thus named white leather.

Regular leather sees the usage of chromium salts in the leather tanning process that are detrimental to the environment. The toxic wastewater discharge, inclusive of the chromium salts, seeps deep into the underground water systems. These chemicals are known to harm human beings and are seen to affect the eyes, lungs, liver, kidney, and lymph nodes of those who come in contact with them.

Thus, this fairly recent development in the tanning industry – white leather – has gained popularity due to the minimal impact on the environment.

The main products used for this white leather or tanning method are synthetic tannins, vegetable tannins, glutaraldehydes and minerals, such as aluminium and zirconium. The best part about this tanning process, apart from being environmentally friendly, is that it emulates the results obtained by using chromium inclusive tanning methods.

Additionally, this white leather is more elastic than regular leather and exhibits a lower level of plasticity.

Advantages:

- The lighter shade of colour can be effectively converted into pastel shades that provide a chic aesthetic.

- Can withstand temperatures up to 70°C

- It’s characterised by a high degree of softness and is very light and pliable

- Has a natural feel and texture that’s at par with that of full-grain leather

- Is very durable and long-lasting. Even outperforms natural leather obtained using a chrome tanning process.

How is White Leather Made?

Considered to be one of the most revolutionary developments in the leather industry, white leather is a sustainable alternative to chromium tanning methods. Over the last few years, this technology has taken off and has efficiently managed to decrease the leather industry induced chromium pollution.

As stated above, the tanning process doesn’t include the usage of chromium salts for the manufacture of white leather. This exclusion makes the tanning process eco-friendly contrary to the chromium tanning process commonplace in the leather industry. An additional upside to this process is that it leaves the base leather just as soft and supple as the veg tanning or chromium tanning processes.

Wet white leathers are produced using synthetic tannins, vegetable tannins, glutaraldehydes and minerals, such as aluminium. The tanning process can be carried out using the same equipment used in veg tanning or chrome tanning tanneries.

White leather is used to manufacture goods like upholstery and clothing that’s susceptible to stains and discolouration. Keep in mind that special care should be taken while cleaning and maintaining this type of leather. Natural yellowing from pollutants and chemical reactions with cleaning products is commonly observed if not maintained.

Conclusion

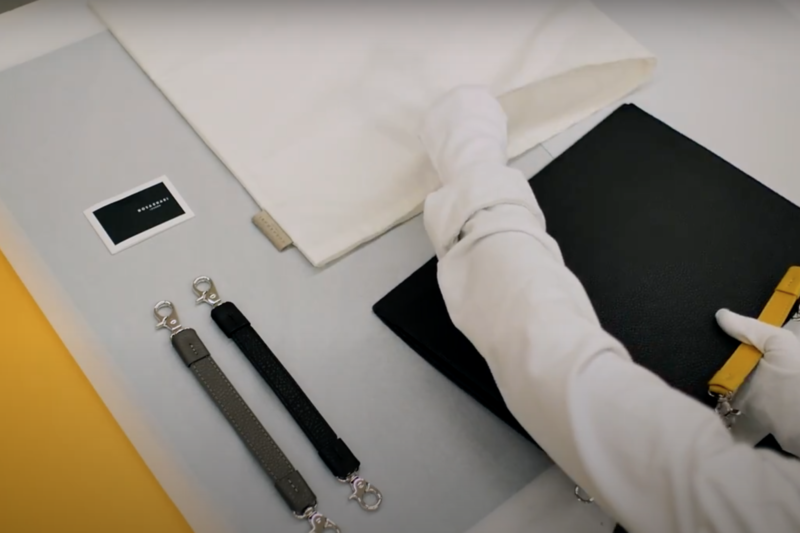

With its unparalleled aesthetic, white leather is growing in stature and demand in the leather market. It’s extensively used in making premium leather goods like handbags, purses and wallets. The only drawback of using white leather products is that it’s prone to natural yellowing if not regularly maintained. Therefore, you need to regularly clean the leather using a linen cloth and remove any excess moisture.

Looking for More?

To learn more about such revolutionary developments in the world of leathercrafting, visit our website and explore more about leather products. We, at CreateLab, also offer our leather production services in the UK and can help you create a white leather product for yourself.

With years of expertise in the leather industry, we, at CreateLab, are pioneers in providing our consultation services to entrepreneurs, even if you’re just starting out in the leathercrafting industry. So if you’re looking to establish a leather business in the UK and want professional advice, then we’ve you covered.

We help leather businesses produce luxurious designs and provide insights into the most suitable leather for their product. Get in touch with us and find out more about our services.